-

2023-12-26

“领十年精彩,赢百年未来”——2023年纽威数控装备员工风华十载纪念活动

纽威工会为工作满10周年(青春贡献奖)、15周年(忠诚敬业奖)、20周年(风雨同舟奖)的员工颁发荣誉证书和纪念品,以表彰他们为公司做出的杰出贡献。

-

2023-12-26

纽威数控荣膺“江苏省机床工具行业年度优秀企业”

近日,江苏省机床工具工业协会颁发2023年江苏省机床工具行业年度优秀企业奖,纽威数控喜获殊荣。

-

2023-12-16

纽威数控装备温馨提示:机床冬季使用注意事项

近期受寒潮影响,气温骤降,为减少低温对机床使用的影响,纽威数控装备特此提示

-

2023-11-24

中国工程院院士周济一行参观纽威数控装备

2023年11月23日,周济院士一行参观了纽威数控装备。他对纽威数控装备中高端市场定位和大力度的研发投入,给予了高度评价,期待纽威数控装备为中国制造做出更大贡献。

-

2023-10-19

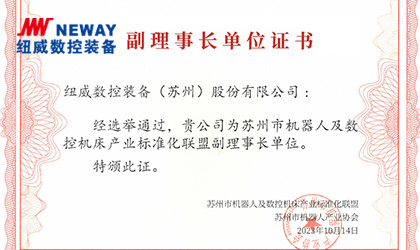

纽威数控当选“苏州市机器人及数控机床产业标准化联盟”副理事长单位

纽威数控作为首批副理事长单位正式加入联盟,参与联盟首批团体标准的研制并且作为苏州市机器人产业质量创新联合体成员代表发起质量倡议。

-

2023-09-22

“大跨度移动式重型龙门加工中心关键技术及其应用”“双驱双排高端卧式加工中心关键技术及其应用”项目顺利通过科技成果鉴定

2023年9月13日,公司研发的“大跨度移动式重型龙门加工中心关键技术及其应用”及“双驱双排高端卧式加工中心关键技术及其应用”项目顺利通过省级科技成果鉴定。

-

2023-09-19

“重型立式车铣磨复合加工中心VNL400HT”荣获 江苏省首台(套)重大装备认定

2023年江苏省首台(套)重大装备认定名单公布,纽威数控装备(苏州)股份有限公司榜上有名

-

2023-09-19

纽威数控装备闪耀第二届全国技能大赛:助力人才选拔与产业进步

2023年9月19日,中华人民共和国第二届职业技能大赛(以下简称“第二届全国技能大赛”)在国家会展中心(天津)圆满闭幕。本次大赛由人力资源社会保障部主办,天津市人民政府承办。大赛以“技能成才、技能报国”为主题,是我国规模最大、水平最高、影响最广的综合性国家职业技能赛事。

-

2023-09-04

纽威数控签约中华人民共和国第二届职业技能大赛

8月30日,中华人民共和国第二届职业技能大赛高级合作伙伴签约仪式在天津举行,纽威数控签约此次大赛高级合作伙伴。

-

2023-07-27

同心筑梦 智造未来

纽威数控第十期客户高阶培训班开班啦!

上一页

上一页