Present location:

Home ProductDouble Column Machining CenterPM series - High speed direct drive spindle portal machining center

PM series - High speed direct drive spindle portal machining center

- Product Overview

- Product features

- Technical Parameters

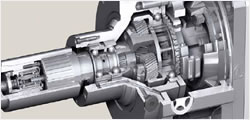

| Portal frame structure, traveling worktable (X axis), spindle box traveling (Z axis), saddle traveling on the beam (Y axis), square ram design and twice speed reducing with gearbox offer low speed constant torque and high speed constant power cutting. High speed, acuracy, agility, To be used for ferrous and nonferrous metal process. Recommend for civil aviation vehicle, resource, IT and pattern industries. |

| tyre pattern > MORE |  | cylinder > MORE |

| fixture > MORE |  | plane parts > MORE |

|  | |

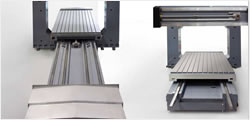

01、integral structure parts go through finite analysis, precisely made with stability | 02、guide rail Imported roller linear guide rail, bi-rail and quadrial-rail structure. | |

|  | |

03、beam guide rail Good deformation resistance design with unloading device to ensure cutting performance and precision. | 04、speed reducing ZF retarder and Neway gearbox increase output torque. | |

Item | Unit | PM0813L | PM1320L | PM1330L | PM1525L | PM1630L | PM1830L | PM1840L | PM2040L | PM2060L |

Worktable width | mm | 1300 | 1500 | 1600 | 1800 | 2000 | ||||

Worktable length | mm | 900 | 2100 | 3100 | 2600 | 3000 | 3000 | 4000 | 4000 | 6000 |

Worktable(X axis) | mm | 800 | 2200 | 3200 | 2700 | 3200 | 3200 | 4200 | 4200 | 6200 |

Carriage travel(Y axis) | mm | 1300 | 1500 | 2100 | 2700 | 3200[3700] | ||||

Ram travel (Z axis) | mm | 700 | 700 | 800 | 800[1000] | 1000 | ||||

Column span | mm | 1400 | 1600 | 1800 | 2300 | 2800 | ||||

Spindle speed | r/min | 15000 | 15000 | 100-10000 | 100-12000[BT40:15000] | 1000-10000[BT40:15000] | ||||

Max.output torque | N.m | 34/46 | 34/46 | 140/165 | 95/118[140/165] | 140/165[BT40:95/118] | ||||

Spindle motor power | kW | 11.7/15.8 | 11.7/15.8 | 22/26 | 15/18.5[22/26] | 22/26/[BT40:15/18.5] | ||||